Diy Resin Mold Silicone / No Mess Diy Silicone Mold Making An Easy How

To make resin molds, gather materials like resin, mold-making material, a mold box, and a release agent. Common mistakes to avoid when making resin molds include not measuring resin and hardener correctly, not using a mold release agent, and not dealing with bubbles.

√ Homemade Resin Molds

Step 1: Select your silicone mold Silicone molds are great for casting resin. They're flexible and come in a variety of shapes and sizes. Here are our customer favorite resin molds: Step 2: Apply mold release Spray a light mist of resin mold release to the mold. Then, let dry for at least 30 minutes before pouring epoxy.

How to Make a Resin MoldFB Resin Crafts Blog

Step 1: Set the temperature to 150F and mix and pour your resin as usual. Step 2: Place your resin-filled mold in the oven for five minutes. Step 3: Check to ensure you aren't melting your mold (mainly plastic mold), and your resin isn't hot and smoking. If things look good, then turn the oven off and let it cool.

Mixed Shape DIY Silicone Molds, Resin Casting Molds, For UV Resin

All you really need for cleaning molds is warm soapy water, you can use traditional washing up liquid for this task. Simply fill up a bowl with the warm soapy water and leave the molds in it to soak for a short while, about 15 minutes will be plenty of time for this. Once they have soaked for a little while you can use a soft sponge to clean.

Popular How To Make My Own Resin Molds Created by Skill hands Kitchen

Check out our molds for resin pouring selection for the very best in unique or custom, handmade pieces from our molds shops.

How to FastTrack Your Success with Casting Molds Resin Obsession

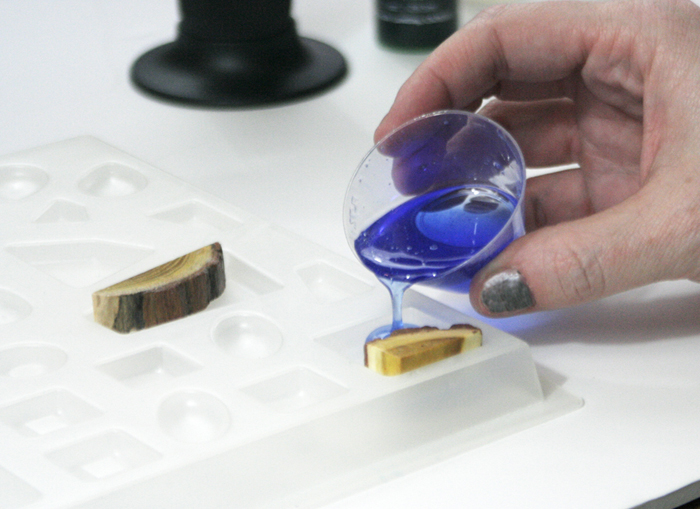

Step by step guide on how to make a mold or form for your epoxy resin table pour. Cart 0.. I can't think of a worse substance to get on a piece of wood before an epoxy pour. Spray your mold release back and forth like a grid over your entire form. Don't forget the sides. I will let the mold release set for a couple minutes, then use a.

WOOD AND RESIN PENDANT USING EASYCAST

https://www.artresin.comWe're back with another episode of Video Friday!Today we are talking about silicon molds..Silicone molds are super popular with re.

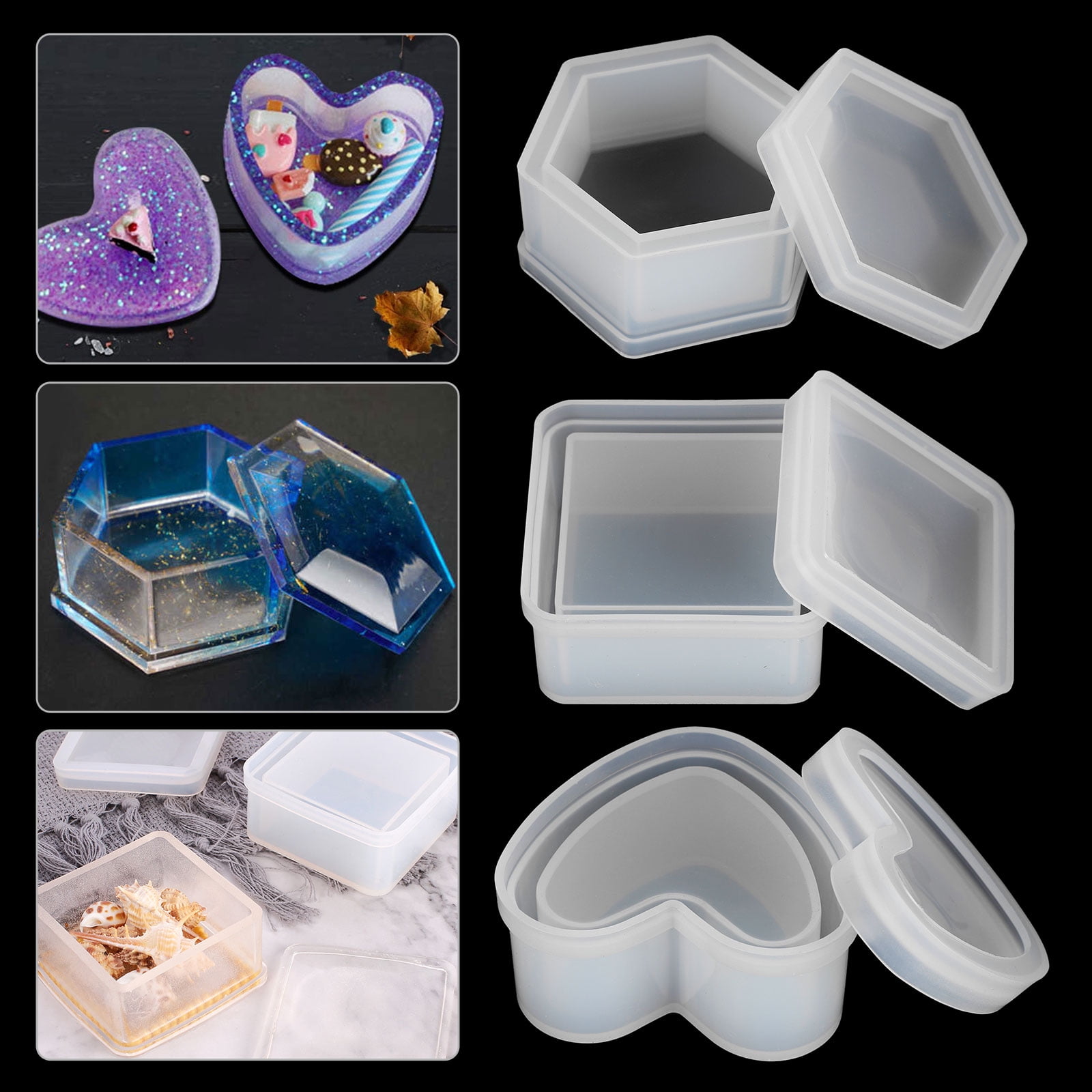

EEEkit 3pcs Silicone Resin Molds with Lid, Jewelry Storage Box Epoxy

This video is a beginners guide to mold making for resin casting. The goal here is to take the intimidation out of mold making. Resin casting can be intimida.

Epoxy Resin Mold Resin Casting Molds Rectangle Silicone Mold Etsy

HDPE Epoxy Molds by Makers Reusable Molds Revolutionize your Epoxy Pours - Save Time, Effort & Money. Highest Quality, Self-Leveling Molds - Rounds, Ovals and Coffee Table Molds/Rectangles HDPE (High Density Polyethylene) WILL NOT bond with Epoxy Resins, these Molds are Built to Last and are simple to clean.

Handbook The Ultimate Guide to Resin Molds 2022 Updated

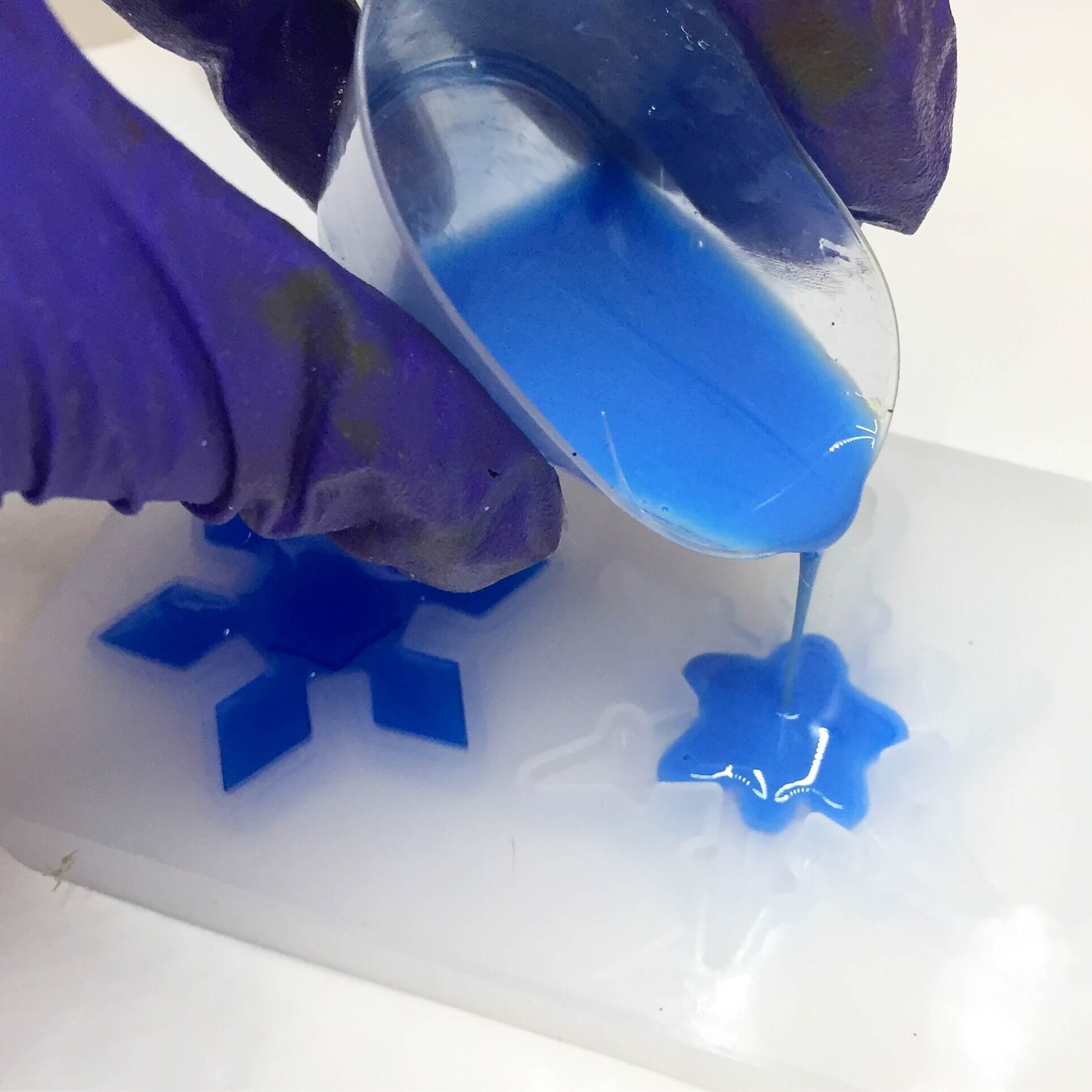

Pour the resin into the mold: Slowly pour the resin mixture into the mold, filling it up to the desired level. You may want to use a stir stick or toothpick to help guide the resin to fill in any areas.

Crystal ball resin mold Gem silicone molds silicone molds Etsy

AFFILIATE LOYALTY REWARDS FAQ USD $ | United States Making resin molds may seem a little daunting, but with the right help, the job is a breeze. Follow these instructions to learn how to make a resin mold.

Resin Molds Resin Silicone Molds Epoxy Resin Mold Resin Mold Perfect

AFFILIATE LOYALTY REWARDS FAQ USD $ | United States Resin mold is a great place to start your DIY projects! Taking care of it is really important. This article will walk you through 5 simple steps when you're working with your resin molds.

Large Resin Molds Silicone Pyramid Molds,Epoxy Resin Molds Including

These can all be done by resin casting, which is to make a mold of the desired item and then pour plastic resin into that mold. While it's easier to write about, it's actually a little more time-consuming in real life and there are many steps to the process. The desired item must be prepared for the mold, the mold and the resin for the part.

Everything You Need to Know About Casting Resin Molds Clear Casting Resin

1- Check Your Tools 2- Don't Mix Epoxy Resin Brands 3- Be Careful about Mixing Your Resin Ratio 4- Prepare Your Wood 5- Be Mindful of Where Your Resin is Curing 6- Never Ever Add Water 7- Pour Slowly 8- Add Coloring Slowly 9- Deal with Bubbles Quickly 10- Look for Non-Stick Molds 11- Start Simple 12- Learn from Your Mistakes

How to Make Resin Bowls Resin Obsession

Never miss a new video! Subscribe here: http://bit.ly/2vFDNAl _____Pouring resin into tight spaces can get messy, especially if you're using.

How I Make Molds for Resin Casting Silicone Rubber Mold YouTube

It is a manufacturing process that involves pouring preheated liquid materials into the mold cavity. The liquid will later cool and harden to create the desired object. You will remove the mold and pack it as the end product for the market. The entire process of resin casting involves the use of synthetic resin. Basics of Resin Casting