Sack and rub finish bridge concrete barriers.AVI YouTube

The invention discloses a construction method of carborundum anti-slip strips. The construction method includes the steps of slotting of a foundation, preparation of materials, pre-embedment,.

Authentic Carborundum Abrasive Combination Sharpening Stone Singapore Eezee

What is slip resistance and why it is important? Slip resistance is measuring the capability of a surface to reduce the risk of accidental falls in both wet and dry conditions. It depends on the finish of a surface (smooth or textured) and various environmental conditions which influence the likelihood of a person to fall.

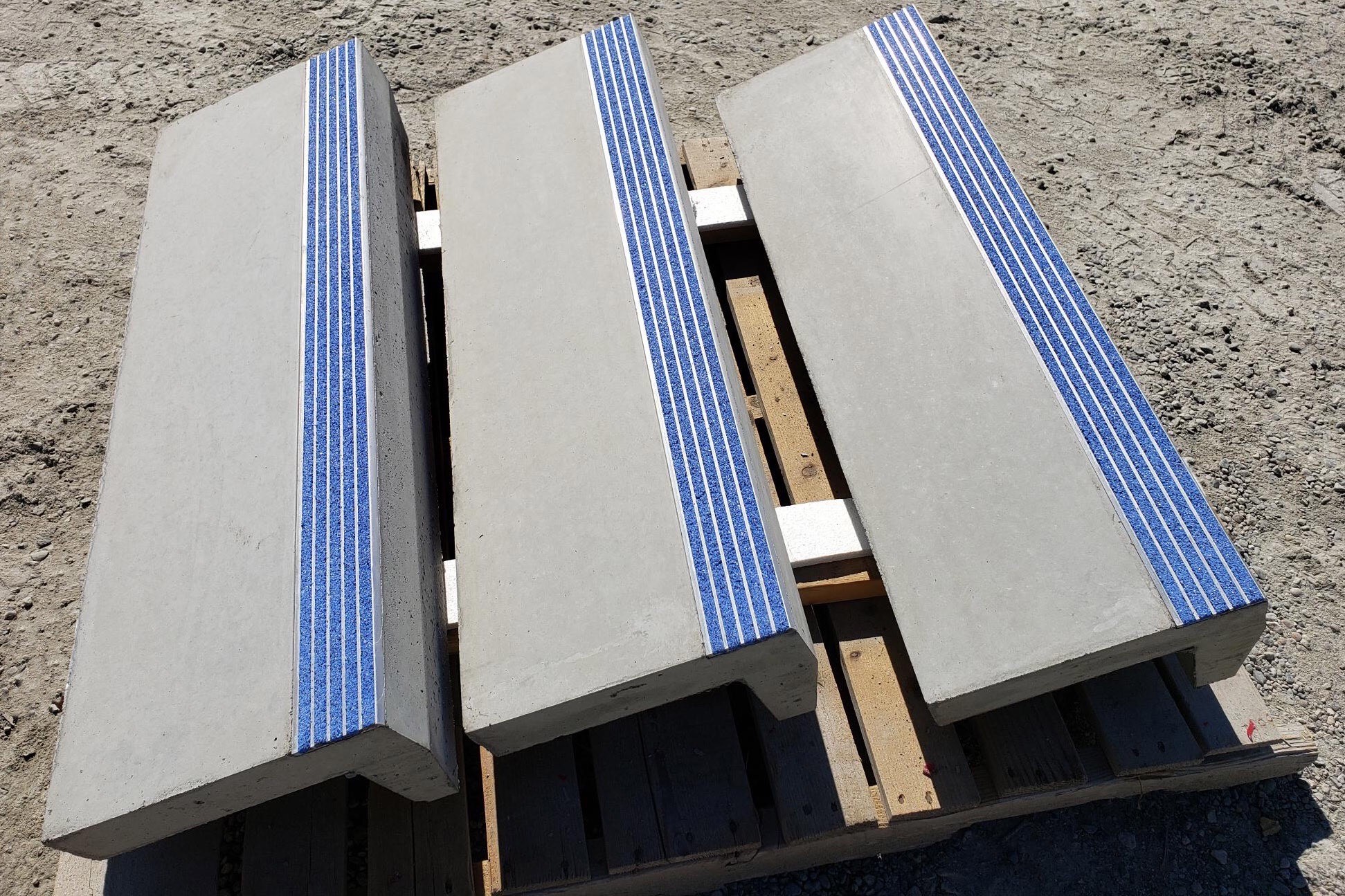

MagmaStrip™ antislip carborundum inserts Magma Safety Products ESI External Works

trowel finish. A trowel is a steel blade or blades (either handheld or motor operated) used on the surface of newly placed and floated concrete to create a dense, smooth, and hard result with good wear resistance. A trowel finish is most commonly used on interior slab and floor applications. However 'Fresno' trowels may be used for exterior.

Outdoor use fireproof Carborundum insert Stair Nosing MSSNC6 Buy Stair Nosing, Aluminum Stair

Concrete: Low: Moderate to low: If textured finish or a non-slip aggregate is used, potential for slip can be low: Concrete (powerfloat finish) Low:. Slip- resistance may be improved by incorporating a carborundum finish. Polished granolithic should not be used for stair treads. GRP, profiled (chequer plate)

Granolithic screed when to use it, and how to choose it

A Carborundum stone will also fill up most of the smaller air holes, if the concrete is no more than a day or two old. To patch holes left by form bolts or ties, clean the hole by pushing a piece of cloth through it to remove grease of form oil. Next, wet the hole. Then ram the mortar well into it with a rod.

Hexagon rock Cut Out Stock Images & Pictures Alamy

The new ACI 301-10 Specifications for Structural Concrete lays out the requirements for Surface Finish-1.0, -2.0 and -3.0 and Unspecified As-Cast Finishes. Essentially, the requirements for the.

bluecarborundumprecastconcretetreads 1 Sanderson Concrete

The use of Davco Carborundum Top Coat on any exterior concrete surface provides a durable, long-lasting finish that has improves resistance to chemicals, oil, grease, and abrasion. ADVANTAGES Offers excellent slip resistance for slippery surfaces such as stone surfaces, pebble wash surfaces, and concrete Finishes.

Carborundum Abrasives 99383 Carborundum Abrasives Fibratex FlexLoc TR Surface Blending Discs

Product Details The Marshalltown 6 in. x 3 in. 20-Grit Concrete Rub Brick with attached handle is ideal for removing form marks from concrete. Also used for smoothing and dressing down concrete and wet tile.

CARBORUNDUM STONE FLUTED 50 X 50 X 200 EHM

A. CONTRACTOR shall supply all labor, tools, equipment, and materials to finish properly placed concrete for structures. 1.02 RELATED SECTIONS The following is a list of SPECIFICATIONS which may be related to this section: Section 03 11 00, Concrete Forming. Section 03 31 00, Structural Concrete. Section 03 60 00, Grouting.

Carborundum Grit

1970: Specifications required a rubbed finish with a carborundum brick on an exposed wall for a county jail in Illinois. The specified concrete strength was 3000 psi at 28 days and the forms were removed in a day. At that time, the fins were removed, and the wall was rubbed, creating enough paste to cover bugholes and fine lines.

Carborundum Abrasives Fibratex FlexLoc TR Surface Blending Discs 12512 Free Shipping on

When sprinkled on wet concrete Carborundum Grit (Silicon Carbide) produces an extremely hardwearing non slip surface. Grade 20 (coarse grade) is held in stock, and is particulary suitable for milking parlour floors. Click on the right hand image and roll over image to see size compared to a 20p coin. Data sheet here Loading zoom

Carborundum Abrasives Resin Cloth Grinding Discs 20354 Free Shipping on Orders Over 99 at

Carborundum Abrasives offers product and pricing solutions for any level of user application and depth of experience for a total commitment to your project.. sanding, or finishing need, Carborundum delivers. Carbo Premier Red. Depressed center wheels are engineered in specific thicknesses for cutting, grinding or light cutting and grinding.

Marshalltown 6 in. x 3 in. 20Grit Concrete Rub Brick840HD The Home Depot

An average 2-car garage is 18' x 20', or 360 sq. ft. with some being slightly larger in order to have the vehicles fit inside more comfortably. With a cost of $2 - $5 per sq. ft. on average, your garage floor will cost about $720 - $1,800. As the size of the garage increases and the design becomes more intricate, the cost will rise.

silicon carbide/carborundum sharpening stone YouTube

These finishes can be achieved by hand tool techniques, by sawing, by applying an abrasive aggregate, with epoxy resin materials, and by setting non-slip strips in the concrete. Troweling is the easiest way to obtain a non-slip surface, but it is probably the least durable. Depending upon the degree of slip resistance required this method might.

Carborundum 180 "S" Sharpening Stone Malaysia TheWwarehouse

$1.78/sq ft for a wet-rub finish with a carborundum stone (one man can do only about 175 sq ft/day). Simonetti says he'd estimate that the grout-cleaned finish would cost about $1.25 to $1.50/sq ft.

Vintage sharpening stone Carborundum brand grit

FINISHING CONCRETE FINISHING CONCRETE Screeding Hand Tamping Previous Lesson Carborundum Blades Concrete Construction Carborundum Blades Carborundum Blade Low cost, abrasive blades are now widely used to cut green concrete made with soft aggregates, such as limestone, dolomite, coral, or slag.